Biomass silos made of prefabricated ferro-concrete ring segments

We offer you an alternative for traditional silos. These are silos made of ferro-concrete ring segments manufactured by Wolf KG Betonwerke. Silos comply with the fire resistance class F90 to F120 , and are made of concrete class C35/45. Silos meets European norms like DIN EN 14491, DIN EN 12779, DIN EN 14122-4.

Basic data:

- silo diameter: ∅ 5,0 m ∅ 6 m ∅ 7,5 m ∅ 10,0 m ∅ 12,0 m;

- useful volume of silo 2300 m3 (depending on diameter);

- assembly of silo within 2 to 7 days by skilled team;

- ready silo is possible to disassembly and move to other localisation;

- delivery of screw reclaimer is possible on inquiry;

- silo is equipped with steel constructions according to design;

[Not a valid template]

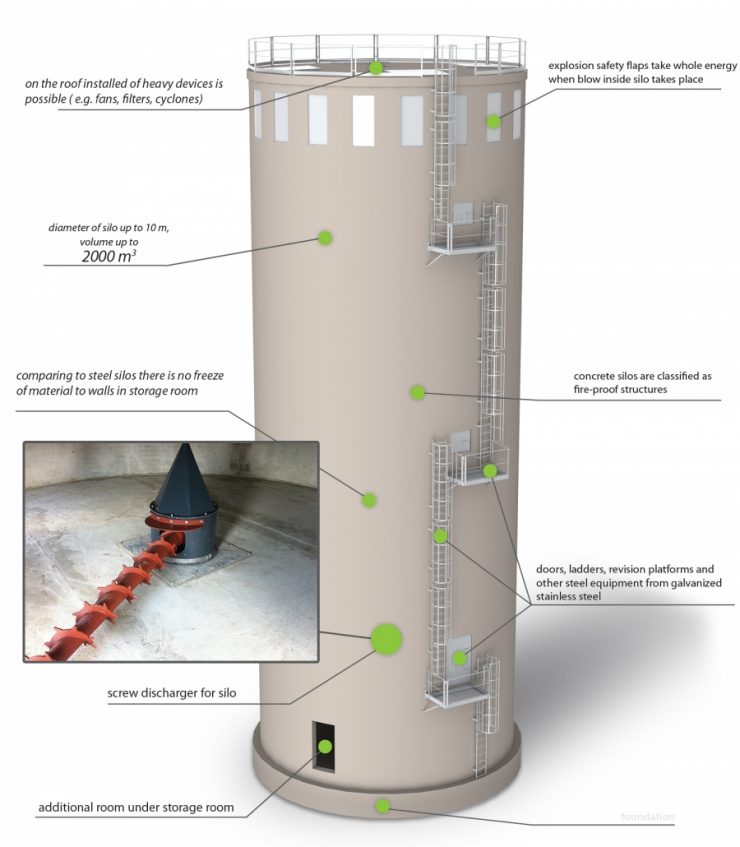

Concrete silos

Data:

- volume up to 2000 m3

- diameter 7-10 m

- total height up to 32 m

Ideal solution for storage:

- wooden dust

- sawdust, shavings

- wooden chips

- agro pellet and wooden pellet

Advantages of concrete silo:

Example of silos:

RANIŻÓW

- silo for storage of chips and sawdust

- volume 950 m3

- as storage silo for boiler w local thermal-power plant

WARSZAWA

- two concrete silos with volume 2000 m3 each

- storage of wooden pellet and agro pellet

- silos for installations co-burning dry biomass and coal in boilers with unit mode

BIŁGORAJ

- two concrete silos with volume 2000 m3 each

- storage of wooden producing waste

- silos nearby boiler in local thermal-power station capacity of 2,6 MW electric power and 10 MW heat power

BARLINEK

- 1-st concrete silo 614 m3 volume for wet sawdust storage

- 2- d concrete silo 2042 m3 volume for dry sawdust storage

- storage silos in pelletizing installation

BIŁGORAJ

- concrete tank for water

- volume 723 m3

- water collected in silo for technological process and fire- fighting as well

MIELEC

- silos for wood waste storage

- volume 1800m3

- silo nearby boiler room supplying heat for technological process and heating to furniture factory

Silo screw dischargers

Advantages:

- silos diameter: up to 25 m

- capacity: up to 800 m3/h

- thanks to frequency converter smooth regulation of capacity

- with additional screw conveyor under outlet capacity can be regulated in range 0-100 %

- central greasing

- simply and easy to assembly

- long life

- low cost of maintenance

Execution screw extractors for other technical data is possible.(on request)

Screw silos design:

Screw discharger in round silo – satellite movement