Biomass HOTAIR generators

Drying with biomass – HotAir-Technology

Our hot air generator systems are manufactured for the energy supply of industrial and agricultural drying plants. With the use of regionally available biomass instead of fossil fuels, the drying costs can be significantly reduced. Flexible technology and years of experience in the design of hot-air systems allow the combination with almost all available dryer models.

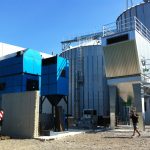

HotAir Generators – industrial technology for high performance up to 10.000 kWth

Hot Air Generators are made with a thermal capacity up to 10.000 kWth and can provide hot air volumes up to 400.000 m³/h and temperatures up to 1000 °C for all drying applications. The robust design allows the use of a wide range of different biomass fuels.

HotAir Compact Generators — mobile compact plants up to 1.500 kWth

HotAir Compact installations from 500 to 1500 kWh is delivered as a ready compact system in container format and can be taken into operation without extensive building work within a few hours. Due to the compact design of the plants, space requirement on site is reduced to a minimum. The systems are mobile by the construction on a steel frame, and can therefore be used at different locations.

Applications for the Biomass HotAir systems:

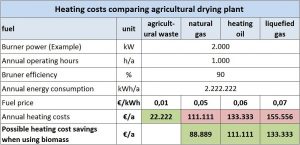

Agricultural drying plants

|

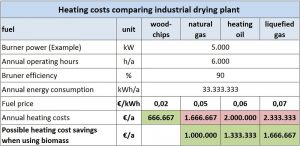

Industrial drying plants

|

Comparing heating cost

|

|

Flexible technology – many applications

Our hot air plants are working with different drying system across Europe. The systems are always specified to the requirements of the drying plant. The flexible design allows to combine almost any drying system with our biomass technology:

- Tower dryers

- Belt dryers

- Feed and turn dryers

- Drum dryers

- Flat grate dryers

- Fluidized bed dryers

- Drying chambers

Gently product drying – indirect hot air generators up to 200 °C

Our indirect hot air systems are used everywhere, where clean fresh air is needed. Especially in the food industry, the indirect drying becomes more popular, since the drying product does not come into contact with the exhaust gases from the combustion process. Through the use of an efficient and specifically for biomass designed exhaust gas / air heat exchanger, clean hot air can be produced up to 200 °C. So also modern drying systems with heat recovery installations can be powered optimally with our technology.

High-temperature drying – direct hot air generators up to 1.000 °C

For drying of mineral products such as sand or stones, high drying temperatures are required. With our biomass fired, direct hot air systems can be provided, depending on fuel humidity, hot gas up to 1000 °C. The combustion gas from the biomass combustion is mixed in a mixing chamber with cold air and the required drying temperature is automatically regulated. About optional hot gas fans also overpressure drying systems (such as fluidized bed dryers) can be combined with our systems.

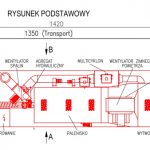

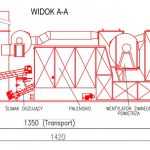

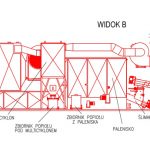

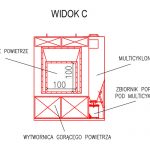

Drawings:

More: